Detailed Information

| Item No | Shipping time | Origin | Brand name | Shipping port | Payment method | Color | Size (width): mm | Material | Packing |

|---|---|---|---|---|---|---|---|---|---|

| NHI-OV200 | 7-15 Days | Vietnam | DynaPex | Hai Phong | TT, L/C, etc. | Black, blue, yellow, orange, white (customized) | 200mm (customized) | Top-grade Polyvinyl Chloride (PVC) resin | 20m/roll |

Product description

DYNAPEX PVC Waterstops are at the forefront of advanced technology and design, meeting international standards

such as ATSM, BS,etc. DYNAPEX PVC Waterstops are extruded from specially Top-grade Polyvinyl Chloride (PVC)

compound, the basic resin is Virgin Polyvinyl Chloride . They are engineered for use in both water-retaining and

water-excluding structures where a positive seal is required for construction, expansion and contraction joints

in concrete. Concrete structures are only as watertight as the waterstops that seal their joints. With a range

of designs for both internal and external applications, when embedded into the concrete, DYNAPEX PVC Waterstops

create a continuous barrier, making them ideal for preventing water penetration. DYNAPEX can customize our PVC

Waterstop to suit your project’s specific requirements and the material property specifications of your project.

We also have available designs for you to choose from and reference. For more information and diagrams, refer to

the product brochure.

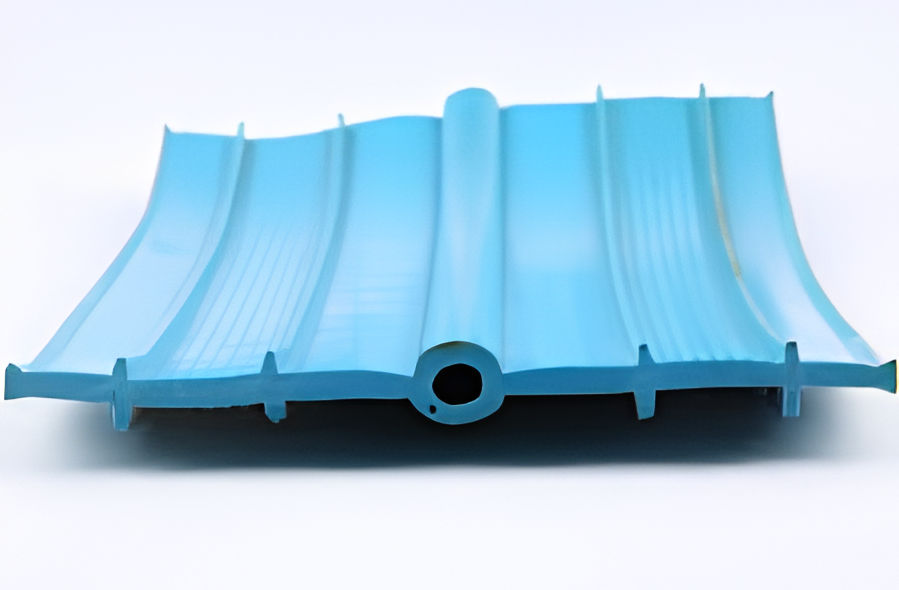

Cross Sectional

Usage

- – Water treatment plant & reservoirs

- – Dams, canals water reservoirs

- – Lock and aqueducts Systems

- – Tunnels and channels

- – Swimming pools and portable water tank

- – Foundations and Slaps on ground

- – Walls and Sub-floors

- – Bridges and Retaining Walls

- – Hydropower and Irrigation constructions

To select the most suitable product for your construction application or project, please refer to our Selection

Guide

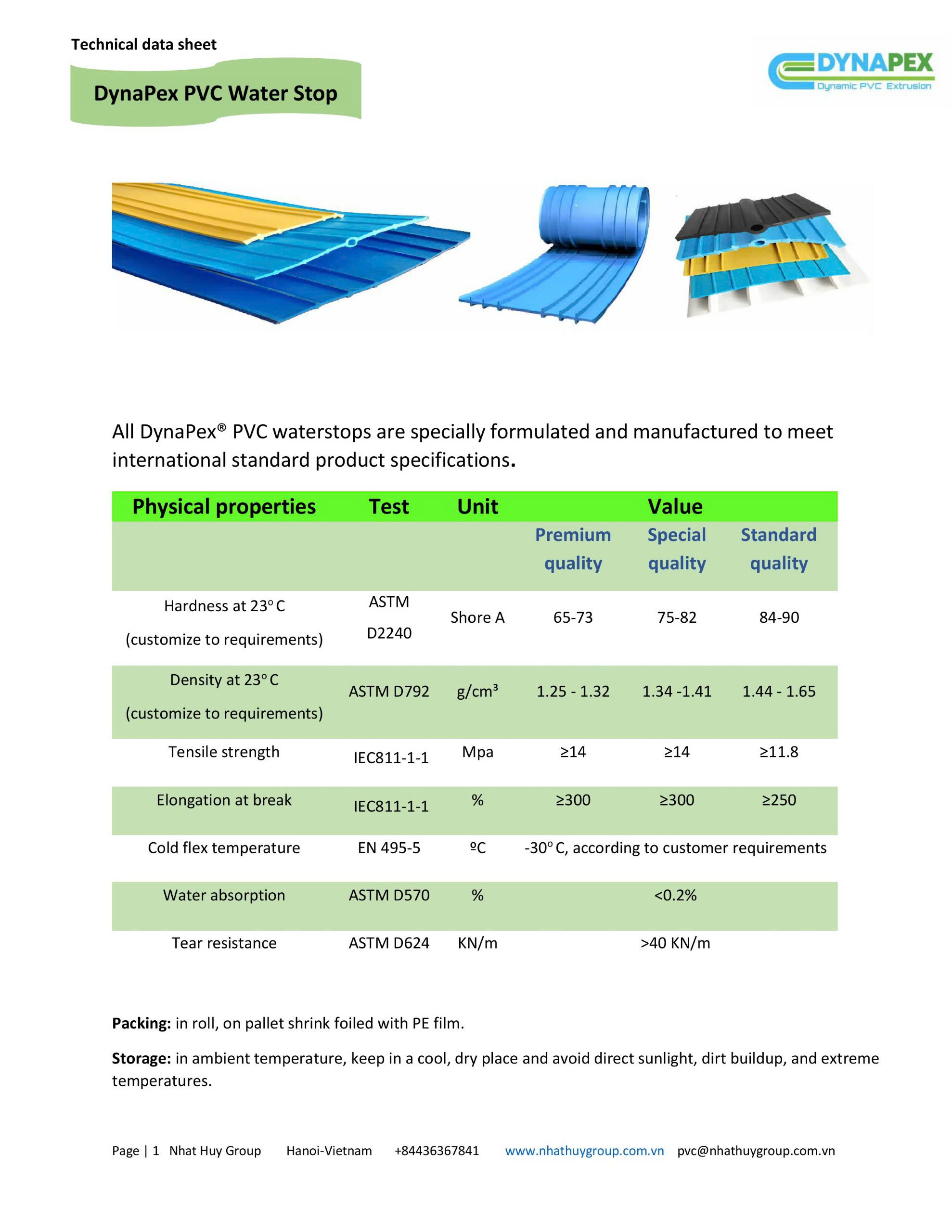

Physical Properties

Installation

- 1. Prepare the Joint Area: Ensure the concrete joint area is clean, free of debris, and any

irregularities. The surface must be smooth for the PVC Waterstop to fit properly. - 2. Position the PVC Waterstop: Place the waterstop at the center of the joint where sealing is

required. For centrally placed waterstops, ensure it aligns perfectly with the center of the concrete slab. - 3. Secure the Waterstop: Use steel bars, clips, or other securements to hold the PVC Waterstop in

position. Avoid puncturing the waterstop, as this can compromise its sealing ability. - 4. Concrete Pouring (First Half): Pour the first half of the concrete while ensuring the PVC

Waterstop remains in place without shifting. Be sure to vibrate the concrete to eliminate air bubbles around

the waterstop. - 5. Check for Proper Alignment: Before pouring the second half of the concrete, double-check the

alignment and position of the PVC Waterstop to ensure it’s securely embedded and properly centered. - 6. Concrete Pouring (Second Half): Pour the second half of the concrete, again ensuring proper

compaction around the waterstop to prevent voids or gaps that could lead to leakage. - 7. Welding or Splicing: For longer sections, PVC Waterstops can be welded on-site using specialized

tools. Clean the ends, heat them with a welding tool, and press together to form a secure, seamless

connection. - 8. Inspection and Testing: After installation, inspect the waterstop placement to ensure there are no

gaps or misalignments. Conduct any required tests to verify the seal’s integrity.

By following these steps, the PVC Waterstop will create an effective barrier against water leakage, ensuring

long-term performance.

Storage Instructions

- 1. Keep in a cool, dry place: Store the product in a well-ventilated area away from direct sunlight,

moisture, and extreme temperatures. - 2. Proper stacking: Ensure that the product is properly stacked to avoid deformation or damage. Avoid

placing heavy objects on top. - 3. Cover if stored outdoors: If outdoor storage is necessary, cover the product with protective

material to shield it from rain, dust, and UV exposure. - 4.Maintain cleanliness: Regularly check and clean the storage area to prevent dust or dirt buildup on

the product.

These steps help ensure the product maintains its quality and extends its shelf life.

Advantages

- 1. Highly effective waterproofing

- 2. High tensile strength

- 3. Excellent elasticity

- 4. High adaptability to movement, expansion, and shrinkage of concrete

- 5. Flexible and intelligently responsive to harsh environments and temperature changes

- 6. Alkali and chemical resistance

- 7. Self-extinguishing and natural fire resistance

- 8. Does not cause discoloration of concrete

- 9. Easy to install

- 10. Versatile applications

- 11. Simple and convenient for transport and storage.