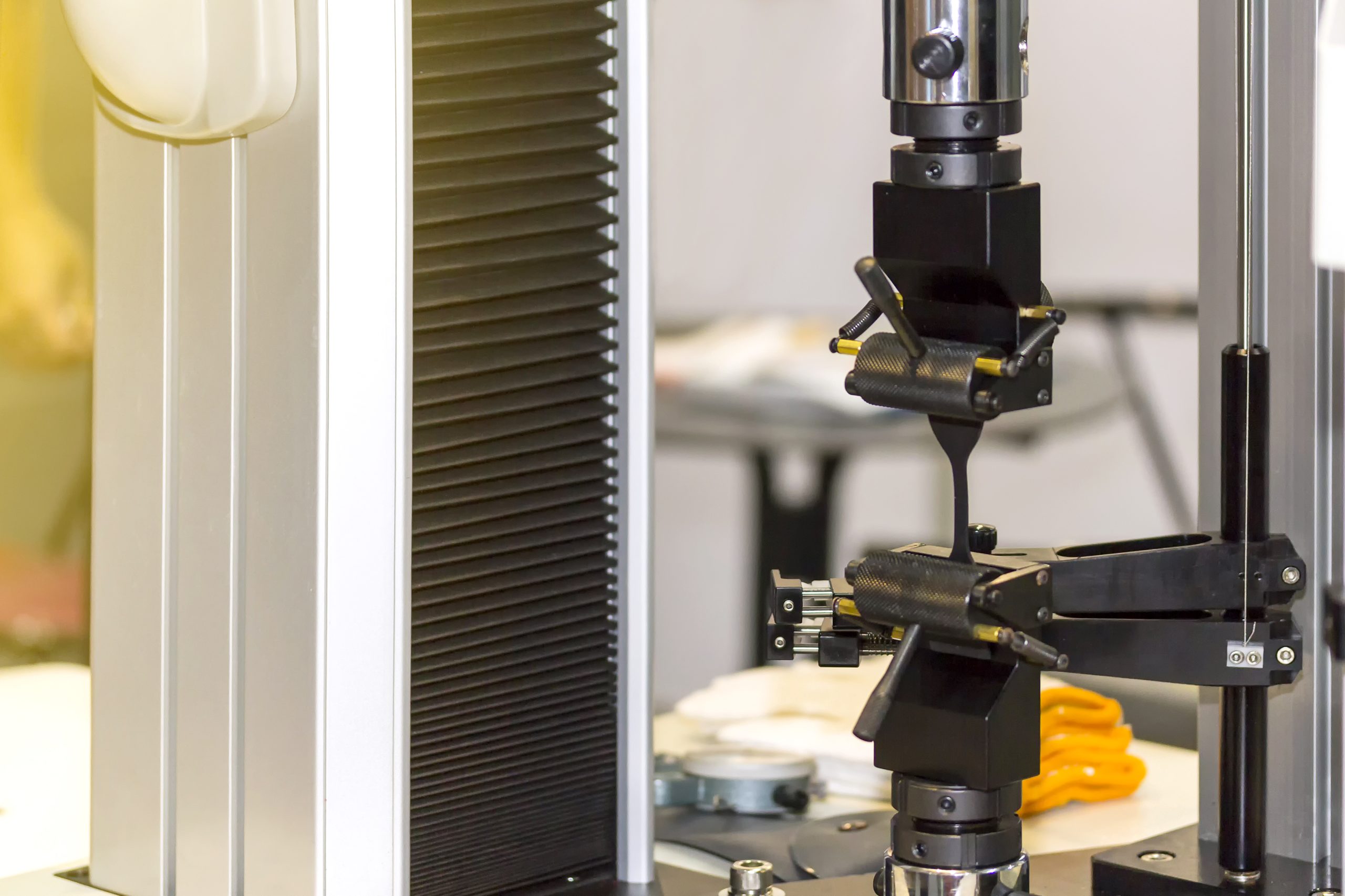

Unwavering Commitment to Quality Through Stringent Raw Material Testing

At Green PVC, the foundation of our high-quality PVC compounds starts with the exceptional standards we set for our raw materials. We understand that superior products are created from superior inputs, so our raw material testing and sourcing protocols are rigorously designed to ensure consistency and excellence in every batch we produce.

Our Approach to Raw Material Excellence Rigorous Testing:

All raw materials entering our factories undergo comprehensive testing to verify their quality and suitability for PVC compound production. This rigorous evaluation ensures that only the best materials are used, supporting the high standards our customers expect.

Reputed Sources:

PVC Resin: It is sourced from Formosa Taiwan, which is known globally for its high-quality resin, which offers excellent durability and performance.

Calcium Carbonate: We utilize a self-sufficient source of calcium carbonate, ensuring quality and a consistent supply that keeps our production lines running smoothly without interruption.

Plasticizers: Sourced from Akyeung Korea, our plasticizers are selected for their ability to make PVC flexible without compromising the material’s integrity. They play a crucial role in the creation of our flexible PVC compounds.

Additives: Our additives, which include stabilizers, fillers, and modifiers, are carefully chosen from trusted suppliers to enhance product performance, from improving weather resistance to increasing longevity.

Ensuring Consistency and Compliance

Our commitment to stringent raw material testing is not just about maintaining product quality; it’s also about compliance with international safety and environmental standards. By controlling the quality of our inputs, we ensure that our outputs meet and exceed the regulatory requirements of different markets, protecting both our clients and the end-users of our products.